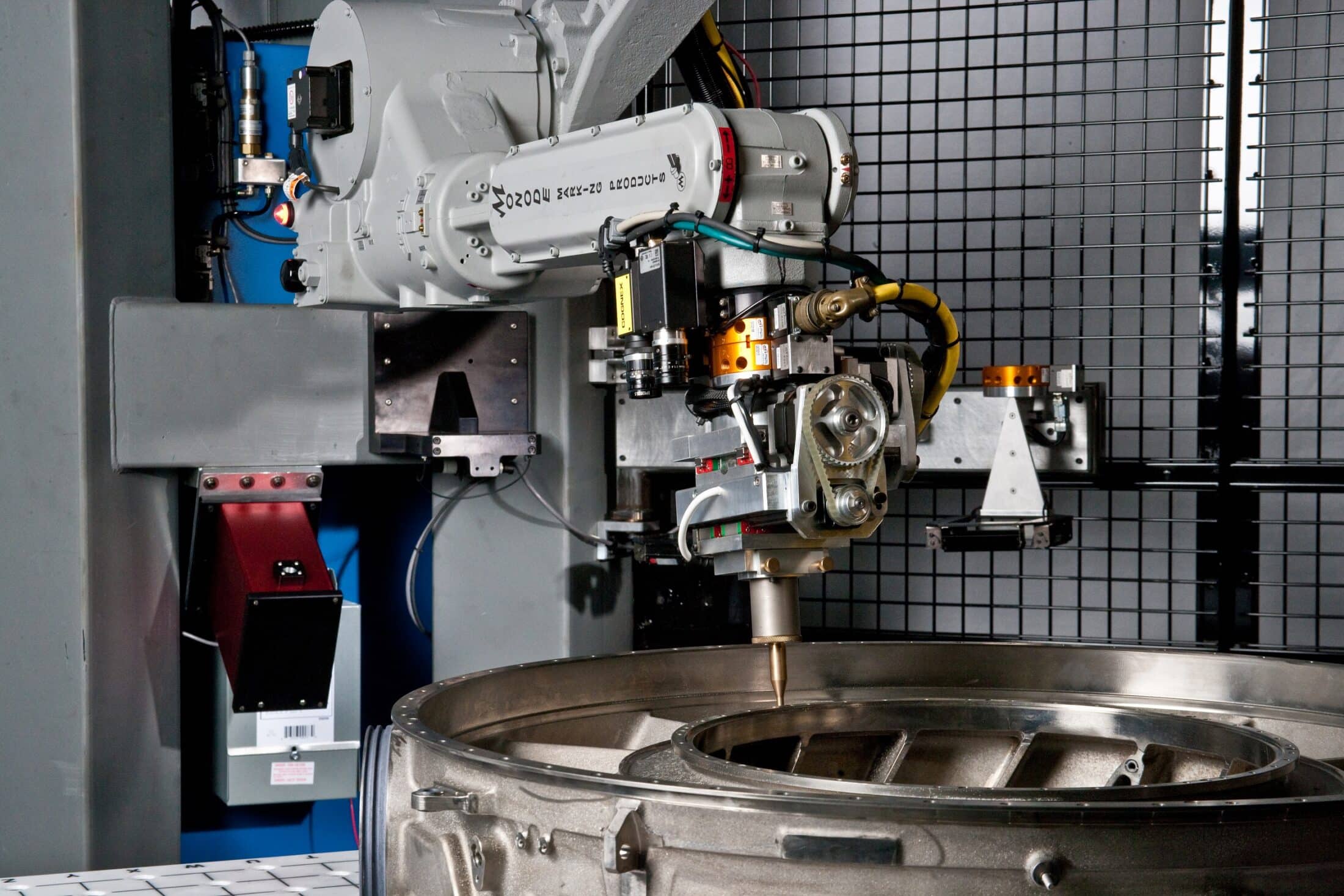

Challenge – The USAF had a large amount of legacy parts that needed to be direct part marked. The cost of fixturing each of the parts was not viable. The challenge was to make a system that could mark any part put on a table with common hold down tooling and have a full repeatability from part to part.

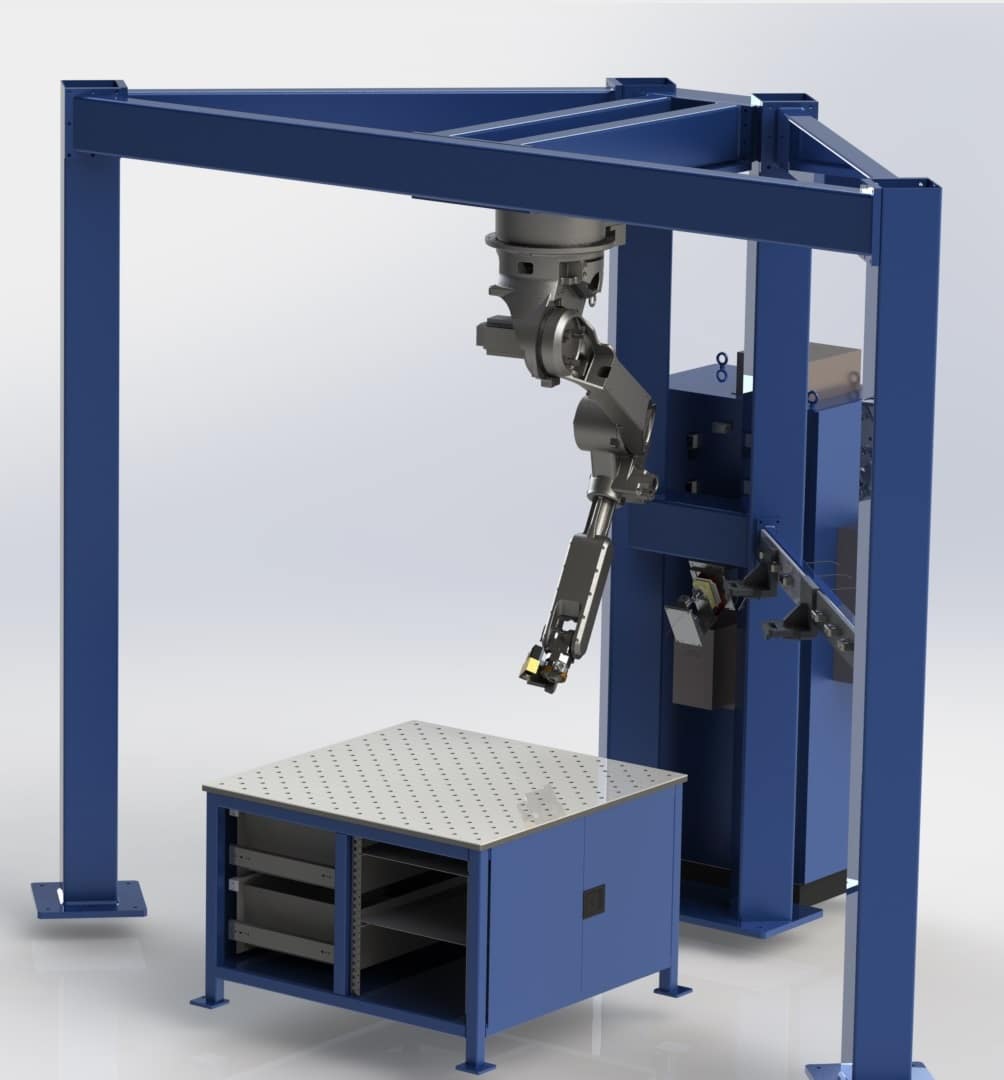

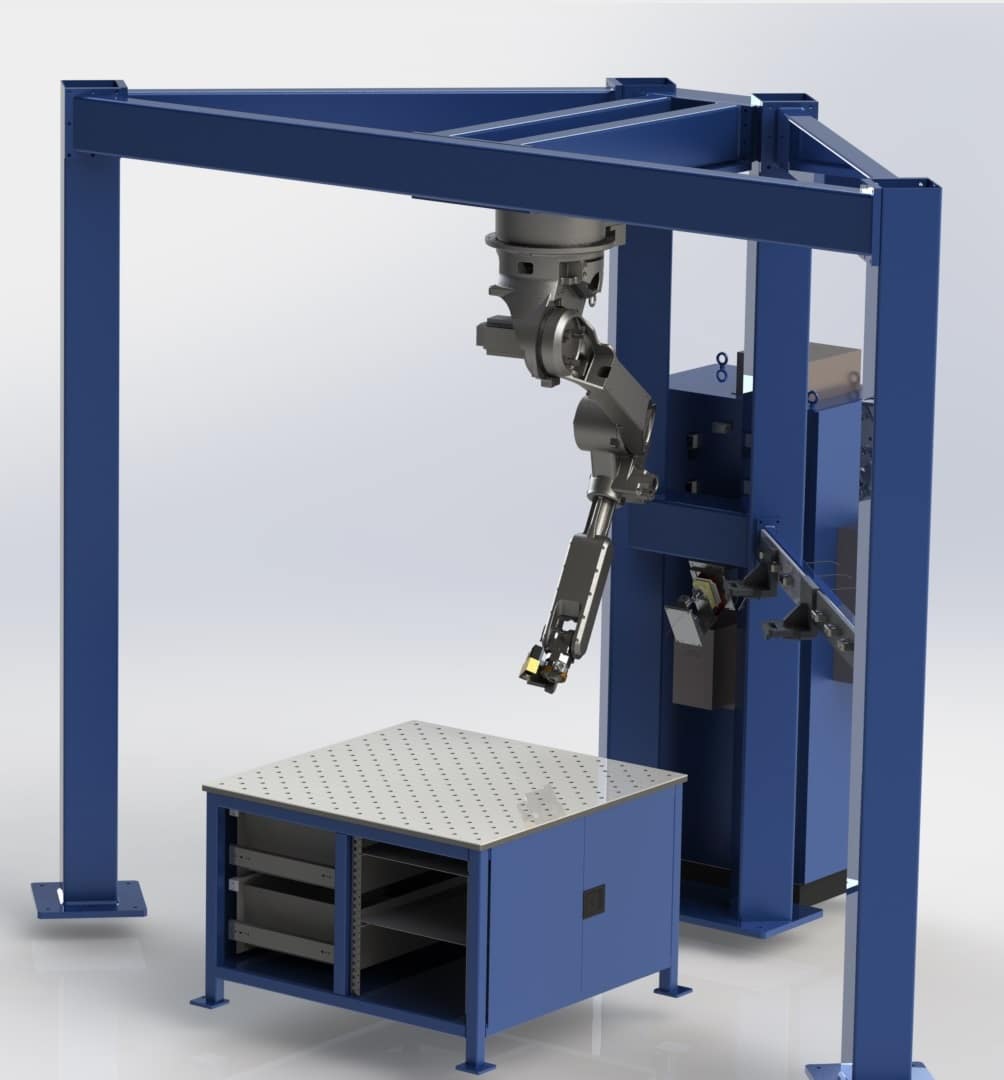

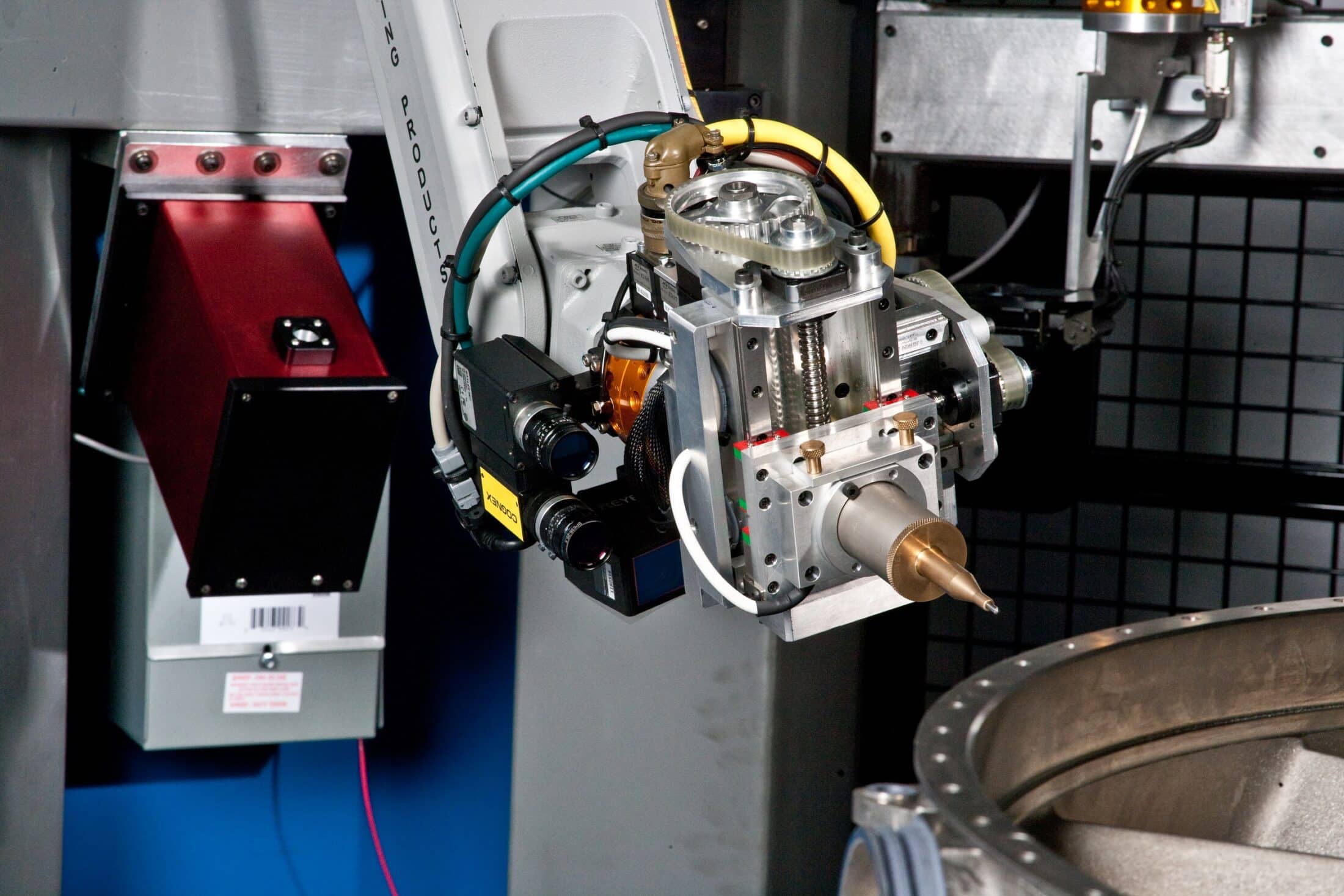

Solution – Monode engineers created a robotic pin marking solution. The base of the solution was a known robot integrated into the Triad II/Traceable-IT engine. This solution had to have multiple measurement tools and vision equipment to accomplish the challenge.

Results – The following was accomplished:

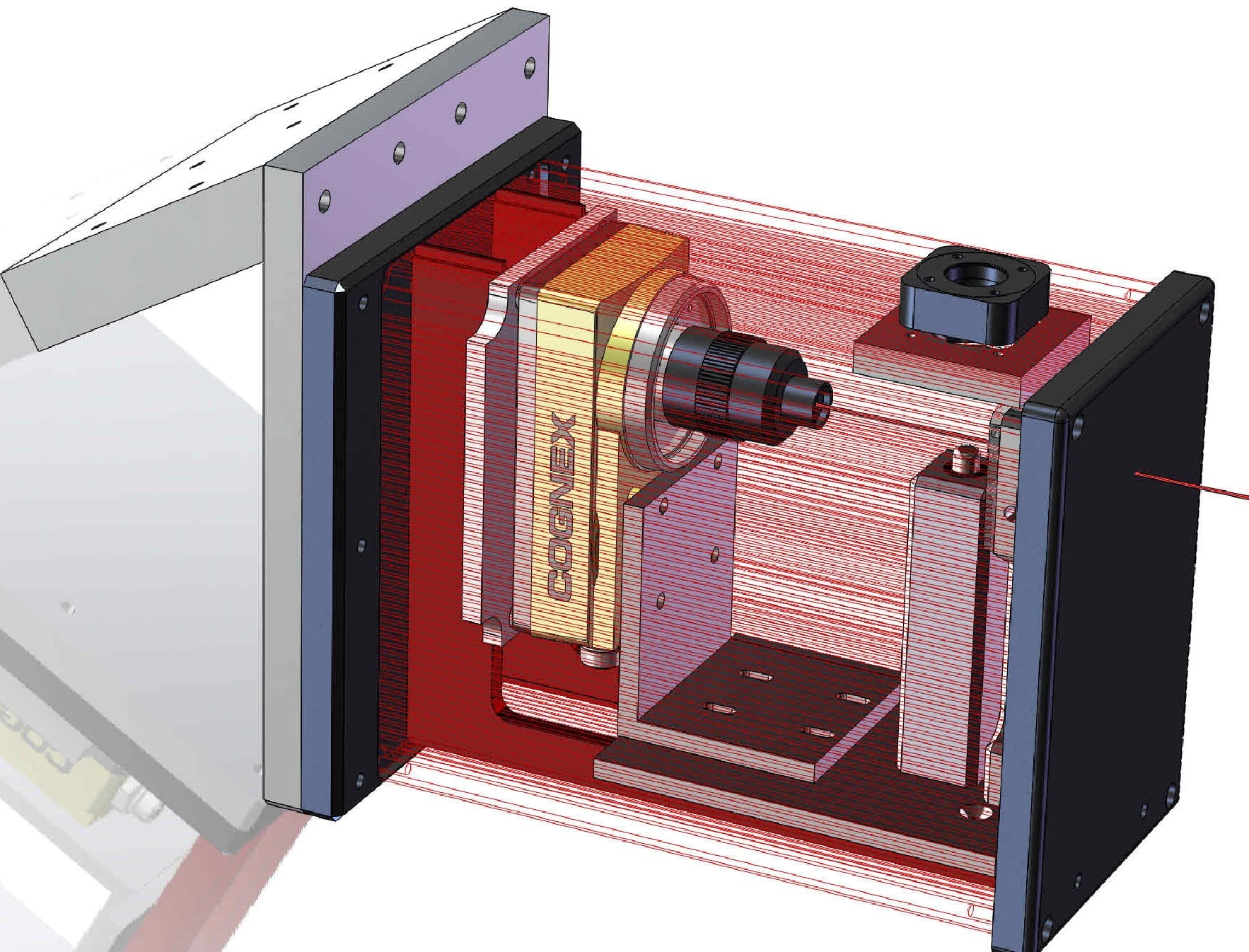

- A vision based pin inspection module was introduce to insure proper pin tip geometry

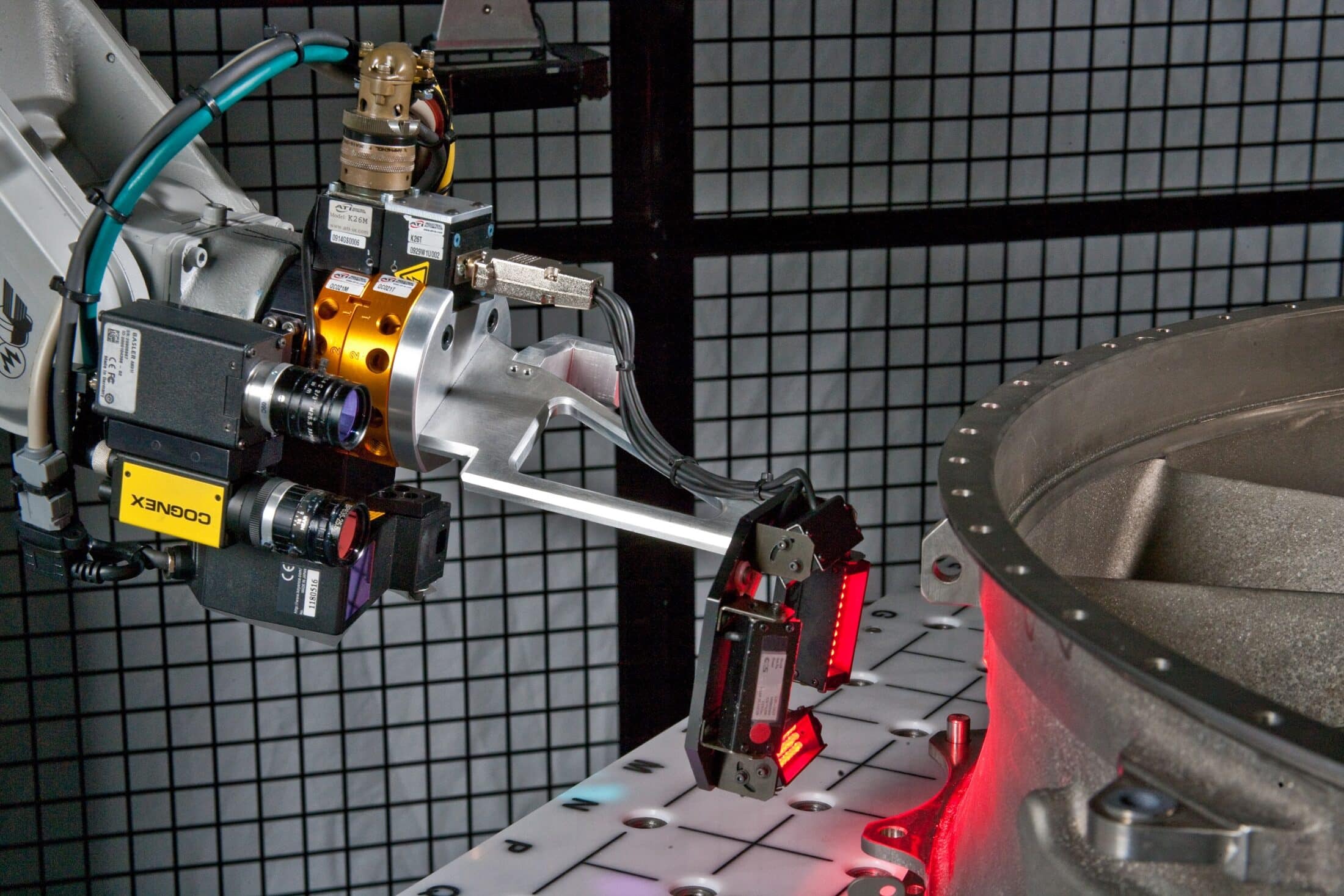

- The system had the ability to “look” at a part, use a laser measurement tool to determine distance and leverage vision tools to find unique areas on parts to use as a starting point

- The robot has a full vision verification system also integrated into the system