At Monode, we intertwine innovation with tradition, crafting cutting-edge marking solutions that set industry standards. Our journey from pioneering the first computer-controlled pin marker to leading today’s marking technology embodies our commitment to excellence and precision.

Founded in 1956, Monode Marking Products has set the standard in our field by providing innovative solutions to contemporary marking problems. We’re a world-leading manufacturer of quality industrial marking equipment for permanent part identification, enabling cradle-to-grave traceability of products.Monode is an original equipment manufacturer (OEM) and distributor of conventional manual marking products, pneumatic and hydraulic presses, and leading edge computer-controlled dot and laser marking systems. Employing highly-qualified mechanical, electrical and software engineers, Monode provides customer consulting services and state-of-the-art turnkey system solutions.

Monode specializes in integrating machine vision and marking technologies into Traceable IT, our proprietary software utilizing existing ERP systems. Our industry specific focus on the DoD, aerospace, automotive, food and drug along with medical markets, make us a clear leader in unit level traceability solutions.

Monode operates from three sites in the US, with continued sales and support in Canada, Mexico, and South America. We service all equipment produced in-house or on-site, as well as provide technical training, sample marking evaluations, and consultations from our experienced sales engineers on the most cost-effective solution to marking problems.

Monode Marking Products has two facilities located in Ohio with a combined total of over 60,000 square feet of advanced manufacturing to help lead the marking industry in production and innovation. At our corporate campus we have equipped our process to meet both standard commercial of the shelf products as well as fully integrated custom engineered solutions. Some highlights of our facility include:

Full machining and manufacturing facility

Training rooms and areas to accommodate meetings and hands-on learning

Full tech center for customer support, technical writing, software development and testing

Engineering and research labs to support any size project

A graphic arts department to compliment the sales staff for any of our customers’ needs

Your business is important to us and we take pride in maintaining a facility that can accommodate any customer’s need in any industry.

Monode is a third generation family owned manufacturing company. Throughout the years we have acquired and incorporated many complementary companies that has helped grow our product offerings and capabilities. These companies are – Waldorf Marking Devices, Lectoetch, Imperial Steel Stamp.

World War II led to the largest increase in industrial production in U.S. history. The aircraft manufacturing industry alone doubled in size each year from 1939 to 1942, becoming the largest single industry in the world.

Over 300,000 aircraft were manufactured in the United States during the war, each built from tens of thousands of individual parts.

This surge in production challenged industry to create new methods for quickly and cost-effectively marking the millions of new parts being created each month. Significant advances in steel stamping and electrochemical etching were made during this era.

Bill and Al Mackey founded Imperial Stamp & Engraving in Chicago. Born during America’s post-war boom and located in the heart of the nation’s manufacturing heartland, the company experienced tremendous growth. Imperial’s revolutionary heat-treated process allowed products to be individually stamped in their hardened state – a major innovation in marking.

Monode was founded in Cleveland and was the first electrochemical etching industry of its kind. Unlike steel stamps, electrochemical etching could mark conductive metal surfaces without compromising the material’s integrity. The manufacturing industry quickly embraced etching and Monode’s early marking units became fixtures in production lines around the world.

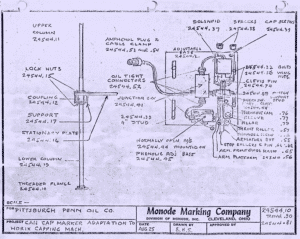

As electrochemical etching spread throughout the manufacturing industry Monode saw an opportunity to revolutionize the process even further. Monode introduced its first automatic system which could operate and synchronize markers, turntables and conveyors on an assembly line. This allowed for fast and reliable duplication of marks in a continuous production environment.

By the 1970s, Monode was frequently working closely with manufacturers to integrate custom automatic marking systems directly into production lines.

Monode developed a reputation that continues to this day as an innovative partner in the design and integration of marking systems.

In 1976, Imperial Stamp & Engraving purchased Monode Marking Products under Bill Mackey’s leadership.

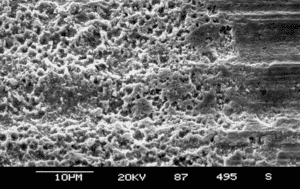

Monode continued to advance the state of electrochemical etching throughout the 1980s through constant research and development.

This scanning electron microscope image commissioned by Monode’s R&D department shows how an etch mark is created by the redeposit of metal oxide onto a conductive metal substrate.

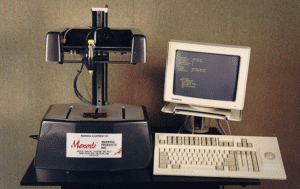

Introduced in the early 90’s, Monode’s revolutionary PMS2001 dot peen marking system featured three independent, computer-controlled axes of motion. This technology allowed for easy integration into the manufacturing process and greater flexibility after installation.

As Monode entered the new millennium, the company made bold advances in marking that were embraced by manufacturers of high precision components for the aerospace, medical and defense industries.

Monode’s Vestige marking systems use a pulsed Ytterbium fiber laser to create fast and flexible markings. The BenchDot dot peen marking systems employ a diamond or carbide stylus to provide precise and deep marks at a high speed. The systems became integral in the marking of everything from eighty-ton crane booms to turbine components for Lockheed Martin’s F-22 Raptor.

Remaining true to the spirit of innovation first embodied by its founders over a half-century ago, Monode continues to pioneer groundbreaking developments for the industry.

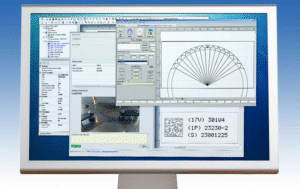

As unit-level parts tracking became critical to the automotive, medical, aerospace and defense industries, Monode responded with Traceable-IT. This software suite ties together legacy systems, marking machines, vision systems and databases to provide cradle-to-grave parts traceability.

Monode is recognized as an expert in the Department of Defense’s UID initiative, which requires a permanent machine-readable Data Matrix barcode on a wide variety of parts. Monode provides both products and services to help vendors achieve and maintain compliance.

BRINGING IT ALL TOGETHER

Remaining true to the spirit of innovation first embodied by its founders over a half century ago, Monode continues to pioneer groundbreaking developments for the industry.

EXCELLENCE THROUGH PRECISION

With the full in house capability for true turnkey fabrication Monode is the leader of custom engineering. We make the solution production smart and user ready from delivery.

GOING MOBILE

Monode was first to market to bring Android/ IOS driven marking machines to the palm of operators hands. Our cordless solutions have redefined how the industry approaches mobile solutions.

Thank you for your interest.

Mail us at

sales@monode.comCall us at

Phone: (440) 975-8802"(Required)" indicates required fields